Supercharge your Work Management

No matter which asset management system you’re using – SAP, Maximo or something else – the ENGAGE: Maintenance Optimization solution will increase productivity by simplifying your work management processes.

ENGAGE: Maintenance Optimization is a comprehensive software solution that empowers you to optimize your maintenance processes and maximize efficiency.

With five scalable modules covering Maintenance Strategies, Work Order Planning, Work Order Scheduling, Resource Management, and Strategic Work Management, ENGAGE streamlines your maintenance operations and drives cost-effective maintenance strategies. These 5 modules can be used together or individually based on your organization’s specific needs and requirements.

Built on our low-code software platform, ENGAGE: Maintenance Optimization can be easily configured to match the unique requirements of your maintenance management processes. The solution centralizes all maintenance-related data and processes, providing a single source of truth for informed decision-making. With its user-friendly design and intuitive interface, ENGAGE will help you achieve better resource utilization, reduced downtime, and improved maintenance performance, leading to increased operational efficiency and cost savings.

Maximo Data Simplified

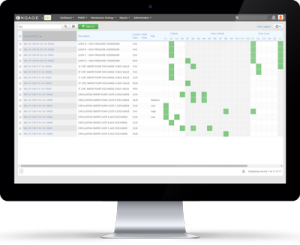

Living Maintenance Strategies

Reduce costs through engineering analysis and justification, without compromising reliability. Leverage aggregated data to analyze current maintenance practices and gain valuable insights into site or system-wide performance. PM templates can be applied to groups of components, identifying outliers and areas where cost savings can be realized. Easily quantify the impact of PM changes, obtain electronic bulk approvals, and write back modifications to the EAM system, streamlining the maintenance process and maximizing cost savings.

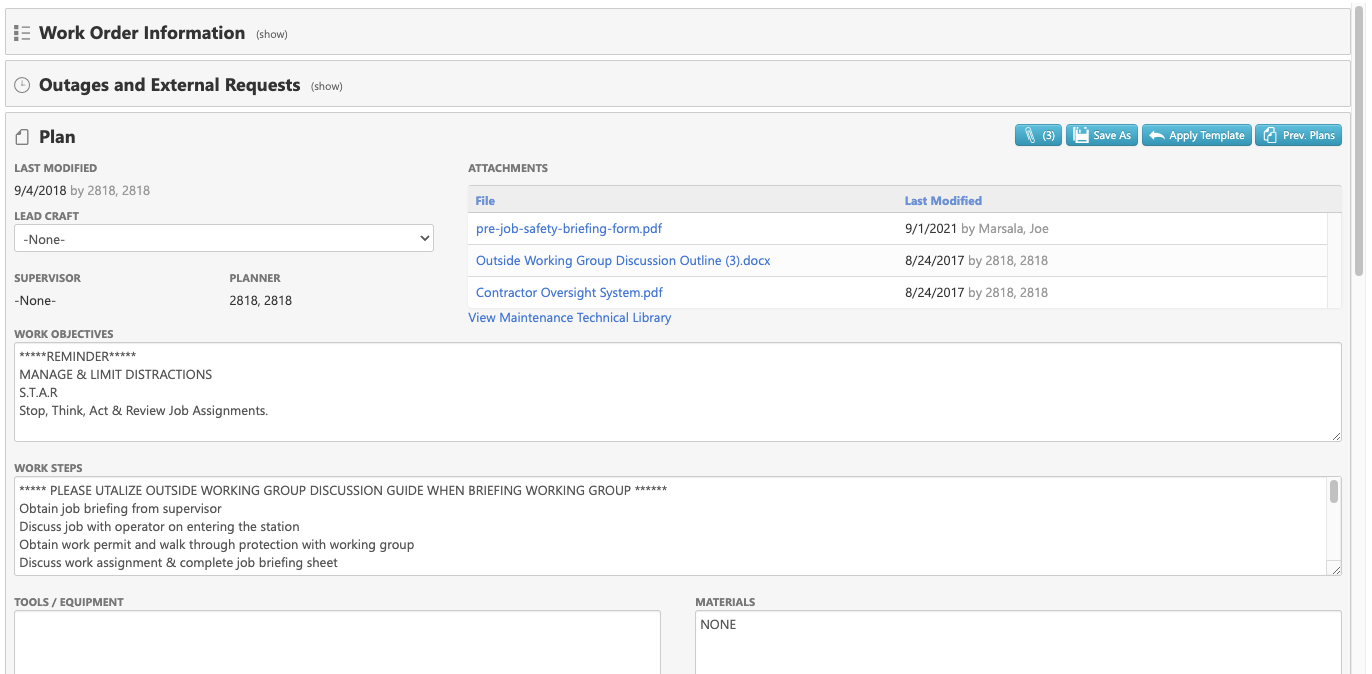

Work Order Planning

Better planning for better execution. Day-specific guidance ensures that assigned resources make the most out of their wrench time, minimizing trips back to the warehouse for forgotten tools or supplies. Better planning leads to more efficient execution, saving time and resources while maximizing productivity.

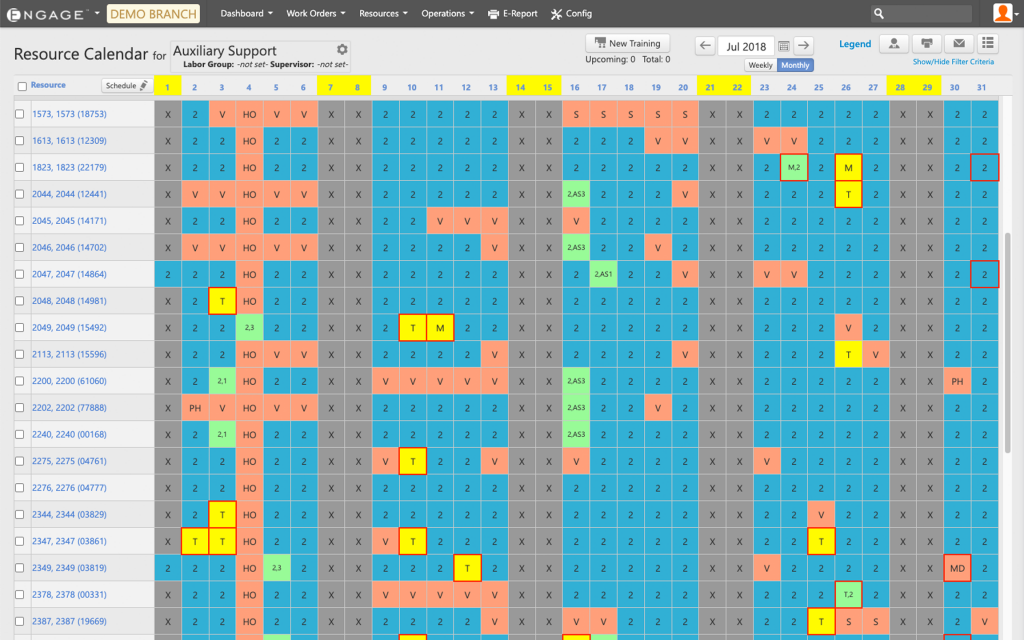

Resource Management

Easily determine who is available, track the number of hours they’re able to work, and automatically generate timecard entries based on scheduled work to reduce administrative burden. When scheduling, quickly see if the scheduled crew has the right skills and qualifications necessary for the job. Automatically pull in training, time off, and other helpful data from other systems to create a realistic picture of resource availability.

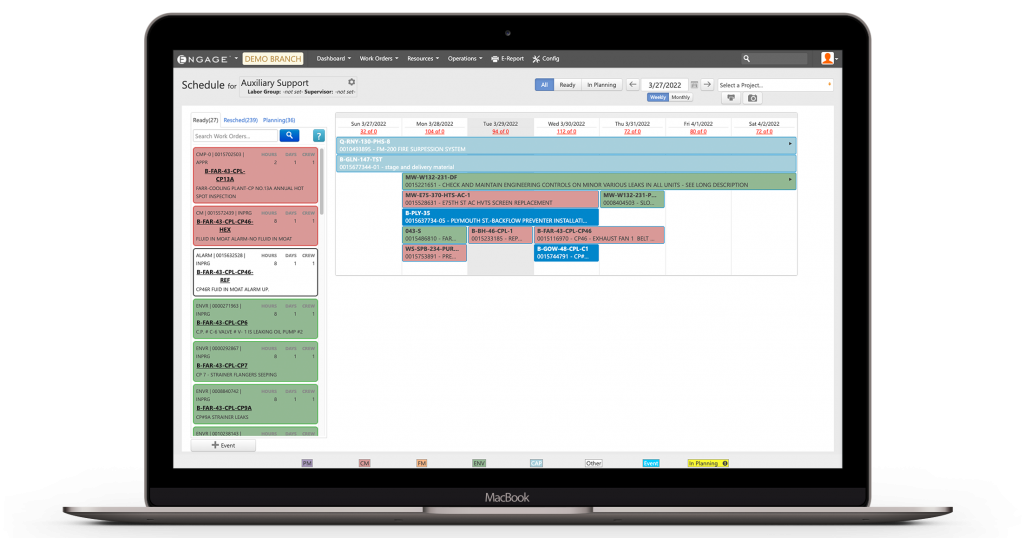

Work Order Scheduling

Drag and drop work order scheduling. The easy-to-use interface consolidates all necessary information in one place enabling work schedulers to operate faster and minimize crew downtime. Get a complete picture of resource availability, including time off, training, and other commitments, estimates, and requirements, increasing the likelihood of completing scheduled work. Color-coded assignment sheets provide a clear and accessible overview of work.

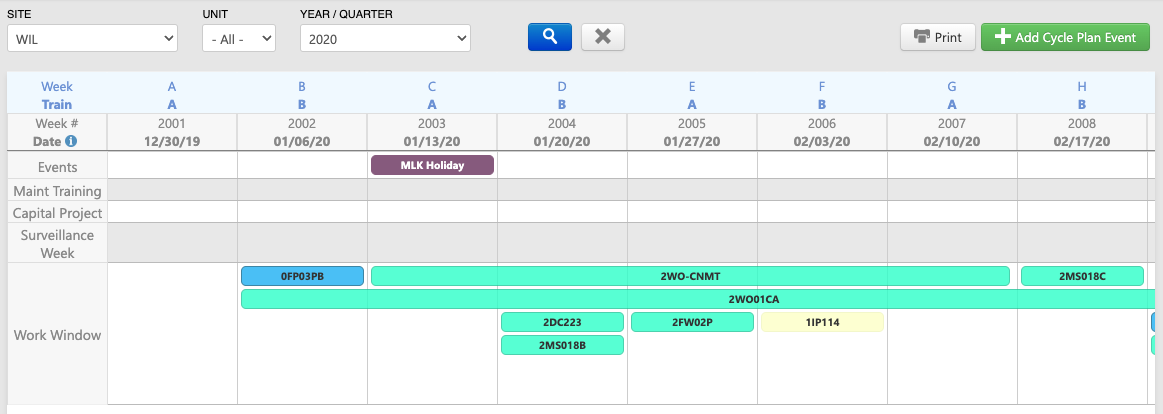

Strategic Work Management

Advanced tools for sophisticated work management. Plan work more effectively over longer time horizons, leading to better resource utilization and reduced downtime. With PM Forecasting, functional equipment groups, and cycle planning functionality, users can gain a deeper understanding of resource demand and manage work more efficiently.